Sunkaier - Model CAPFPR - Agitated Plug Flow Polymerization Reactor

From Chemical Reactors

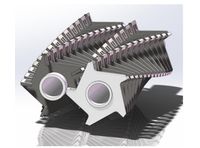

In a CAPFPR, the monomers, solvents, and catalysts are continuously fed into the reactor at one end. The agitator(s) inside the reactor ensure that the mixture is well-stirred, promoting even reaction conditions. As the reaction progresses, the polymerizing material moves through the reactor in a plug flow fashion, exiting from the other end once it has reached the desired conversion and molecular weight.

-

Most popular related searches

Configuration

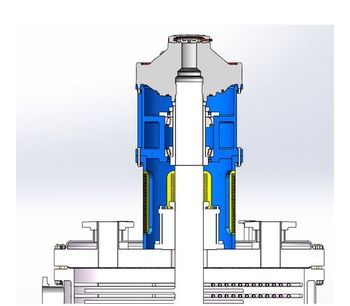

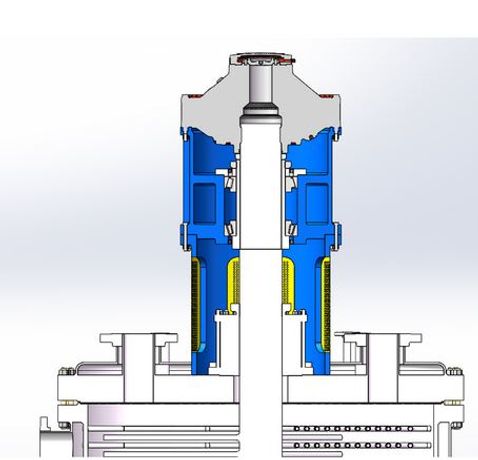

REACTOR INTERAL CONFIGURATION

Related articles

-

Pmma Polymerization Method

PMMA (Polymethyl Methacrylate), commonly known as acrylic, is produced primarily through a polymerization process. There are two main methods for PMMA polymerization: bulk polymerization and ...

Related products

Customer reviews

No reviews were found for Sunkaier - Model CAPFPR - Agitated Plug Flow Polymerization Reactor. Be the first to review!